Would you like to know a simple recipe for happiness? It's cheese with black truffle. It's made in Grodno and sold all over Belarus and beyond. The product got an extensive exposure thanks to Aleksandr Lukashenko. In March 2021, while visiting the Molochny Mir dairy company, the head of state toured the production workshops and also sampled the local products. It was there that the president was treated to a new cheese containing natural truffle. It has the right balance of proteins and fats, and also contains tryptophan, an amino acid that influences the production of serotonin, commonly known as the happiness hormone. Aleksandr Lukashenko assured that he would definitely eat the cheese. “After all, everyone wants to be happy,” he stated. In a new episode of BelTA's YouTube project “After the Fact: Special Report” we will show how this “serotonin bomb” is produced and tell you who, and why, comes to the factory hungry.

How is milk quality tested

Almost 100% of the milk supplied to the factory is of the highest and extra grades. This has been made possible through mutually beneficial cooperation between the enterprise and the farms in the raw material supply zone. The factory's specialists conduct seminars and training courses for farms about the modern methods of laboratory testing.

These parameters include protein, fat, and dry residue. Special attention is paid to tracking antibiotics and veterinary drugs, which is critical for safety.

These parameters include protein, fat, and dry residue. Special attention is paid to tracking antibiotics and veterinary drugs, which is critical for safety.

How long does cheese take to ripen?

Ripening is the final stage of cheese production, during which the flavor, aroma, and texture of cheese become fully developed. This process is monitored through tasting.

For example, Krones cheese with black truffle matures for six months at a specific temperature and humidity. All technological parameters must be strictly observed. To ensure the cheese ripens evenly, it is necessary to turn it regularly.

By the way, to win over a demanding customer, the recipe for Krones took a whole year to develop. “We use authentic French truffles to produce this cheese: there should be no doubt about that. We developed the recipe, selected the ingredients, conducted tastings, and studied our customer preferences. Yet we didn’t stop there. We turned to a distinctly Belarusian ingredient, cranberry, and created a cheese with it. We did not stop there either. We continued to produce cheese with white truffle and pumpkin seeds,” said Olga Mikhnovets, first deputy director general at Molochny Mir.

The company noted that this product line is in demand not only in the domestic market but also abroad. Among its traditional partners is, certainly, Russia, while the United Arab Emirates are listed among the new markets.

Almost 100% of the milk supplied to the factory is of the highest and extra grades. This has been made possible through mutually beneficial cooperation between the enterprise and the farms in the raw material supply zone. The factory's specialists conduct seminars and training courses for farms about the modern methods of laboratory testing.

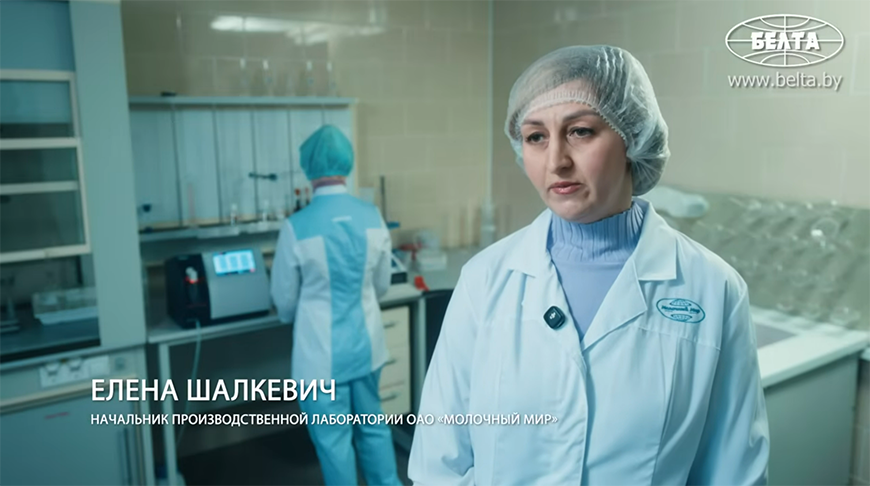

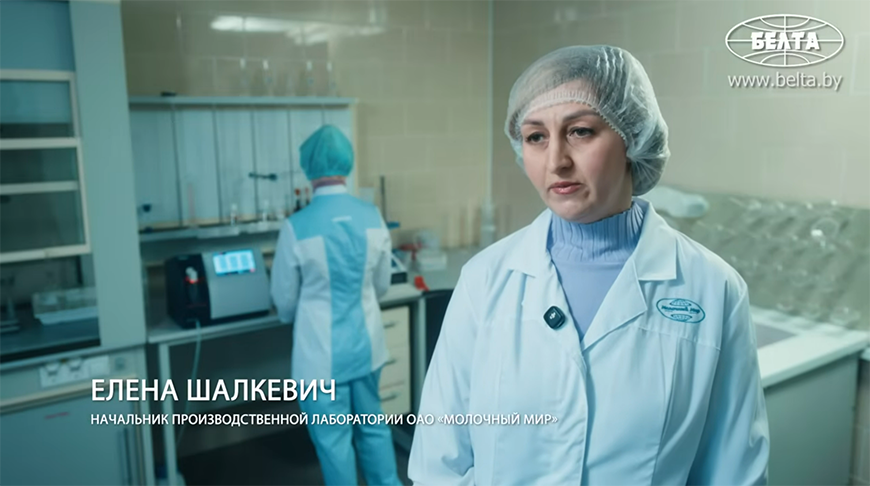

“We have a three-stage control system for raw milk. The farms within our supply zone are the first stage. They are provided with the necessary equipment, take an interest in the devices we use, and often keep pace with us by purchasing new equipment themselves,” said Yelena Shalkevich, head of the production lab at Molochny Mir.

The second stage of raw material testing is conducted on-site by an accredited laboratory. Rapid testing methods are used here. Speed is essential as the facility processes large volumes of milk. “Our equipment allows us to analyze the milk within 10-15 minutes, determining not only the physical and chemical parameters but also the microbiological ones. The grade is assigned based on a combination of many parameters,” Yelena Shalkevich said.

These parameters include protein, fat, and dry residue. Special attention is paid to tracking antibiotics and veterinary drugs, which is critical for safety.

These parameters include protein, fat, and dry residue. Special attention is paid to tracking antibiotics and veterinary drugs, which is critical for safety.

The third stage involves veterinary supervision, where independent experts can perform an inspection at any time. “They visit the facility with representatives of the Grodno Veterinary Station and veterinary supervision services. Following their protocols, they collect samples of both raw milk and finished products from the warehouse. They encode these samples and send them to independent laboratories,” she said.

How cheese is made

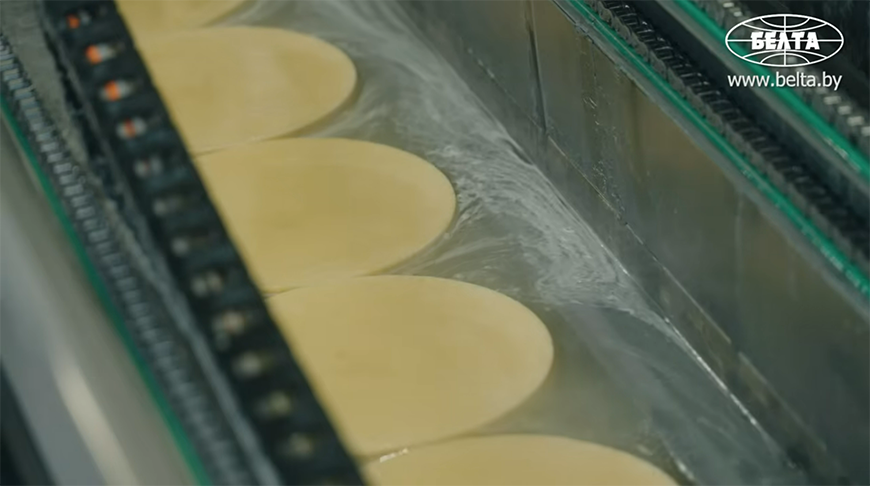

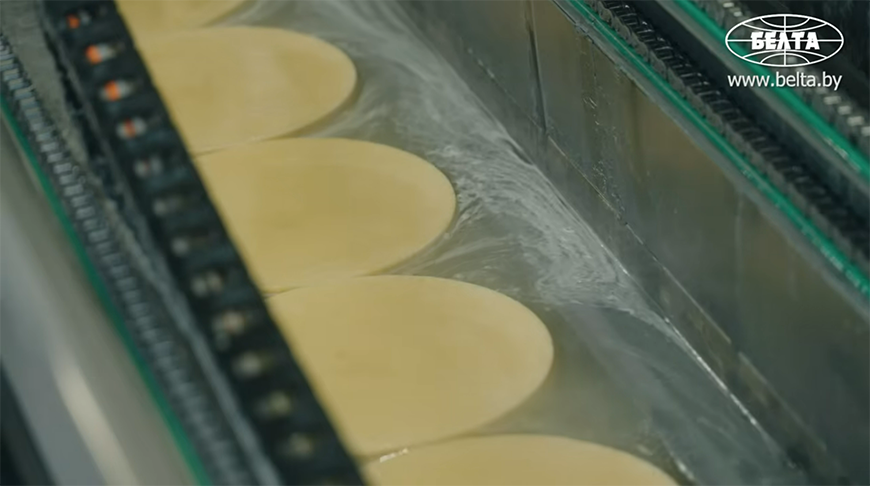

After passing inspection, the milk moves to the receiving and apparatus section. Here, all processes are automated and managed by a single operator. The milk undergoes thermal preparation, is cooled and pasteurized, after which it is transferred to the cheese vats. Here, the necessary components for making the cheese are added.

“One of them is the starter culture, which shapes the product’s eventual flavor. We use a domestically produced starter culture. After all the necessary components are added, coagulation begins, followed by the formation of curds. During production, we add natural truffle to the curds,” Yuri Bondarenko, leading industrial engineer at Molochny Mir, said detailing the production process.

The milk mixture is stirred and then sent to a molding column. The next steps are pressing and marking. A laser etches the production date and time, as well as the serial number of the cheese wheel.

“By ensuring traceability, we can find out which cow's milk was used to make a given piece of cheese,” Yuri Bondarenko said.

Over the next 24 hours, the cheese is salted. “The brine is not just water and salt. It’s a complex technological ecosystem. When its parameters are maintained correctly, it helps form the cheese’s good taste and aroma,” the leading industrial engineer explained.

Ripening is the final stage of cheese production, during which the flavor, aroma, and texture of cheese become fully developed. This process is monitored through tasting.

For example, Krones cheese with black truffle matures for six months at a specific temperature and humidity. All technological parameters must be strictly observed. To ensure the cheese ripens evenly, it is necessary to turn it regularly.

By the way, to win over a demanding customer, the recipe for Krones took a whole year to develop. “We use authentic French truffles to produce this cheese: there should be no doubt about that. We developed the recipe, selected the ingredients, conducted tastings, and studied our customer preferences. Yet we didn’t stop there. We turned to a distinctly Belarusian ingredient, cranberry, and created a cheese with it. We did not stop there either. We continued to produce cheese with white truffle and pumpkin seeds,” said Olga Mikhnovets, first deputy director general at Molochny Mir.

The company noted that this product line is in demand not only in the domestic market but also abroad. Among its traditional partners is, certainly, Russia, while the United Arab Emirates are listed among the new markets.

How cheese quality is ensured

Enterprise specialists monitor product quality and safety at every stage of production. The microbiological laboratory fully complies with veterinary regulations. It tests both raw materials and finished products. Comprehensive sanitary control is carried out across the entire production process: equipment is certified for use, staff clothing is monitored, and even the air in the workshops is carefully checked.

“We are certified to work with potentially pathogenic biological agents of the first risk group. Our quality control covers indicators like coliform bacteria, levels of mesophilic aerobic microorganisms, and the presence of mold, yeast, and staphylococcus. We are also heavily focused on introducing control measures for microorganisms like pseudomonas in production,” the head of the production lab Yelena Shalkevich said.

Finished products are also tested in the production laboratory of the cheese-making shop. Key physico-chemical parameters are fat, moisture, and salt content. There is one facility at OAO Molochny Mir that is a rare sight in the industry – a sensory lab. It was set up here four years ago to perform product tasting and quality control. The experts were trained in Belarus and Russia. They always work on an empty stomach for a more sensitive perception of the taste and aroma.

“Samples are prepared in the first room. Every sample has a cipher with numbers. Then the products are moved to the second room which consists of three cubicles with water supply. Our experts are present in these cubicles,” Yelena Shalkevich offered a brief tour.

Each expert gets a ciphered sample. He or she needs to sample the product within a certain period of time.

“The cubicles are isolated. We don’t want experts to talk to each other as they sample these products. They have to be left alone with their sensory receptors. Once the product is sampled, sensors tell us that the product sample has passed the control procedure. The expert pushes this button and it lights up,” the head of the production lab described the process.”

What cheese did Lukashenko want to gift to Putin?

Then the experts fill in the sampling sheet. They give points to the cheese. This is how new ingredients are tested and the cheese that should be sent to a contest is chosen. However, high praise from the president is a victory, too. And Molochny Mir Company has gotten excellent scores more than once.

Do you remember that story about the Presidential cheese? Literally this summer as he was getting familiar with dairy products of Grodno Oblast enterprises, Aleksandr Lukashenko asked Molochny Mir Company to make a special sample for his Russian counterpart Vladimir Putin. It should bear the Kremlin on the packaging instead of the Palace of Independence.

Leaders of many countries have sampled the Presidential cheese. Not only the Palace of Independence and the Kremlin have been depicted on the packaging. However, it is a totally different story…