News of the story

"After the Fact: Lukashenko’s Decisions"

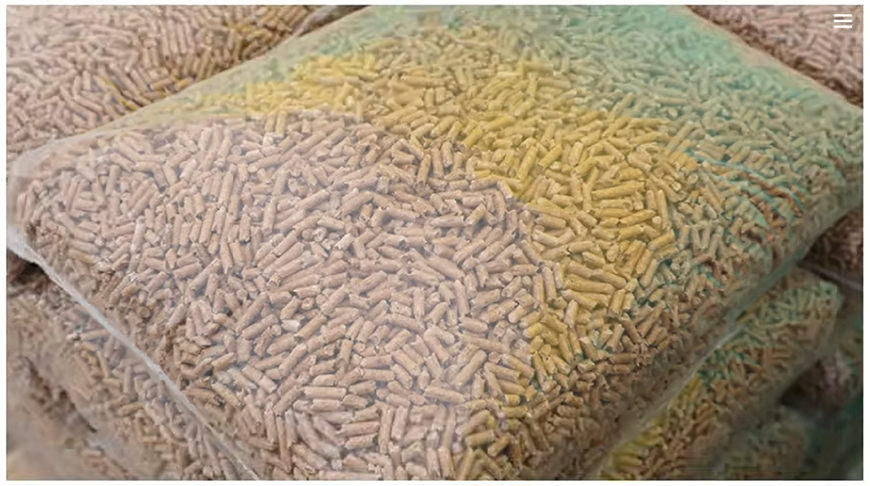

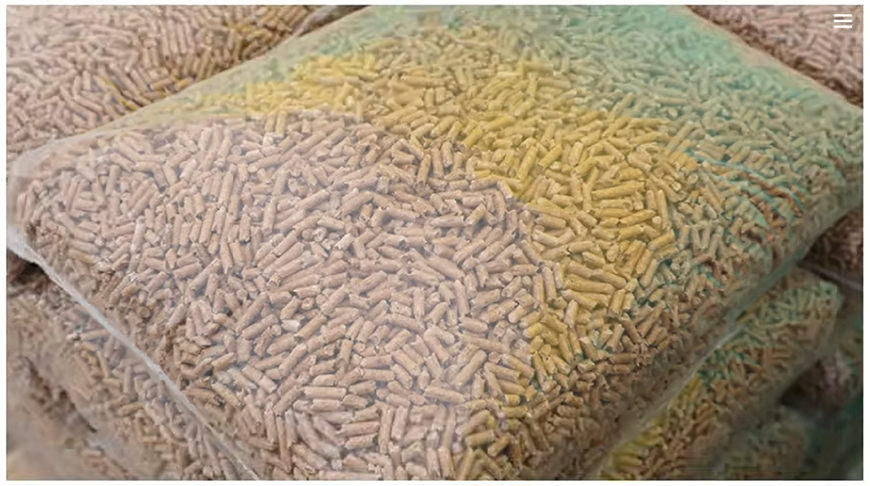

Pellets are fuel granules. They are produced, in fact, from waste wood. Environmentally friendly biofuel can replace coal, oil, gas and firewood. In Europe and some Asian countries, wood pellets have long been used on an industrial scale. In a new episode of BelTA’s YouTube project “After the Fact: Lukashenko’s Decisions” we will explore how pellets are produced. How much does one tonne of pellets cost? How are Belarusians encouraged to switch to wood biofuel? A heads up: l cite a lot of useful figures!

How many pellet production facilities operate in Belarus

There are 64 fuel pellet production facilities in Belarus. They are of different forms of ownership. Almost one third of them are affiliated with the Forestry Ministry.

“All these facilities have different capacities. Starting from small production facilities that produce 300 tonnes per month and finishing with large ones that have a production capacity of more than 100,000 tonnes per year. As far as the Forestry Ministry is concerned, our production facilities basically have a production capacity of about 20,000 tonnes per month,” said Vladimir Krech, Deputy Forestry Minister of the Republic of Belarus.

The total capacity of Belarusian production facilities is estimated at more than 900,000 tonnes per year. Initially, these were export-oriented projects. The global wood pellets market size is huge.

What does Lukashenko demand from wood biofuel producers?

Several years ago, selling pellets to Europe was quite a lucrative business. Back then the manufacturers were given the following task: to sell at a profit and not to compete with each other. This was one of the instructions that Aleksandr Lukashenko gave during his working trip to Vitebsk Oblast in June 2020.

“Well done, your pellet business has shot up. You have built these facilities in no time. You have started producing fuel,” the president said.

That said, he asked the government to make sure domestic producers would not compete with each other in Europe where the demand for such products is huge. “If we start competing with each other, prices will drop and profits will plummet into the negative range. The sale of products should be coordinated by one center,” Aleksandr Lukashenko said.

The economy became hostage to political conflicts. Sanctions made it impossible to keep exporting pellets to the European Union. Aleksandr Lukashenko gave an instruction to explore other sales markets.

“We have agreed on the following: Pellets and more pellets. This is fuel. Having cheap natural gas, we were foolish enough to phase out the production of firewood and other fuels. I do not know the current situation with these pellets, but this should be your biggest priority. We built seven or eight factories last year to process this garbage, this wasted wood, that is in abundance in our forests, and we make excellent goods. Look for other markets outside Europe. And Europe will also have to reconsider its position one day,” the head of state said.

What are fuel pellets made from?

In 2020, the first pellet production facility was commissioned at Borisov Experimental Forestry Enterprise on the Nemanitsa site. Its total annual output is 30,000 tonnes of wood pellets.

“In 2022 we built the second production facility. Our first production facility was constructed to make white pellets. These pellets are used mostly by households. But the pellets made at the second production facility are meant for industrial needs,” said Viktor Amelyanovich, Director of Borisov Experimental Forestry Enterprise.

Light or white pellets are made from wood processing residue. Sawdust, chips are byproducts of the production of sawn timber and moldings. Dark granules are made from 'forest' raw materials. The wood removed during forest clearance cannot be sold, therefore it is used to make fuel pellets.

There are 64 fuel pellet production facilities in Belarus. They are of different forms of ownership. Almost one third of them are affiliated with the Forestry Ministry.

“All these facilities have different capacities. Starting from small production facilities that produce 300 tonnes per month and finishing with large ones that have a production capacity of more than 100,000 tonnes per year. As far as the Forestry Ministry is concerned, our production facilities basically have a production capacity of about 20,000 tonnes per month,” said Vladimir Krech, Deputy Forestry Minister of the Republic of Belarus.

The total capacity of Belarusian production facilities is estimated at more than 900,000 tonnes per year. Initially, these were export-oriented projects. The global wood pellets market size is huge.

“Today, the global consumption of pellets is estimated at more than 31 million tonnes. The main consumers are the UK (over 7 million tonnes), the EU (more than 12.5 million tonnes), Japan (4.5 million tonnes), South Korea (6 million tonnes). Therefore, the products manufactured at these facilities were meant primarily for export,” Vladimir Krech said.

What does Lukashenko demand from wood biofuel producers?

Several years ago, selling pellets to Europe was quite a lucrative business. Back then the manufacturers were given the following task: to sell at a profit and not to compete with each other. This was one of the instructions that Aleksandr Lukashenko gave during his working trip to Vitebsk Oblast in June 2020.

“Well done, your pellet business has shot up. You have built these facilities in no time. You have started producing fuel,” the president said.

That said, he asked the government to make sure domestic producers would not compete with each other in Europe where the demand for such products is huge. “If we start competing with each other, prices will drop and profits will plummet into the negative range. The sale of products should be coordinated by one center,” Aleksandr Lukashenko said.

The economy became hostage to political conflicts. Sanctions made it impossible to keep exporting pellets to the European Union. Aleksandr Lukashenko gave an instruction to explore other sales markets.

“We have agreed on the following: Pellets and more pellets. This is fuel. Having cheap natural gas, we were foolish enough to phase out the production of firewood and other fuels. I do not know the current situation with these pellets, but this should be your biggest priority. We built seven or eight factories last year to process this garbage, this wasted wood, that is in abundance in our forests, and we make excellent goods. Look for other markets outside Europe. And Europe will also have to reconsider its position one day,” the head of state said.

What are fuel pellets made from?

In 2020, the first pellet production facility was commissioned at Borisov Experimental Forestry Enterprise on the Nemanitsa site. Its total annual output is 30,000 tonnes of wood pellets.

“In 2022 we built the second production facility. Our first production facility was constructed to make white pellets. These pellets are used mostly by households. But the pellets made at the second production facility are meant for industrial needs,” said Viktor Amelyanovich, Director of Borisov Experimental Forestry Enterprise.

Light or white pellets are made from wood processing residue. Sawdust, chips are byproducts of the production of sawn timber and moldings. Dark granules are made from 'forest' raw materials. The wood removed during forest clearance cannot be sold, therefore it is used to make fuel pellets.

“We mainly use coniferous wood, dry wood, dead wood for the production of pellets. In general, people do not use this wood for heating purposes. Today, people usually prefer hardwood as firewood. Sometimes, they opt for conifers, but this is a very small amount,” Viktor Amelyanovich said.

Forestry enterprises grind, dry and pelletize raw materials. Two production facilities of the Borisov forestry enterprise produce 50,000 tonnes of pellets a year. Some of it is exported to Russia, Uzbekistan and other CIS countries.

“A number of decisions ensured certain progress in the domestic market. Modernization programs cover boiler houses both in the housing and utilities and energy sectors. We see that the demand on the domestic market will keep growing,” Viktor Amelyanovich said.

Pellets vs other fuels

Let's compare pellets with other fuels. One and a half tonnes of pellets are comparable to one tonne of coal. Pellets are the cleanest type of fuel, while coal has significant negative impacts on the environment. Gas looks more attractive in this case, but it is more expensive.

“Today two tonnes of pellets or a little less are comparable to 1,000 cubic meters of gas. The price for 1,000 cubic meters of gas for legal entities is about Br700. Today prices for pellets are regulated in the country. According to the resolution of the Council of Ministers, the price regulator is the Forestry Ministry. One tonne of pellets costs Br200 without VAT,” Vladimir Krech said.

Prices for individual consumers are different. The price for gas boiler users is a little more than Br200 per 1,000 cubic meters of gas. Pellets lose in the price battle here. Nevertheless, the Forestry Ministry and the government have already done a lot to improve the situation.

“Resolution No.1028 of the Council of Ministers has been amended to include pellets into the list of fuels subsidized by the government. They are sold to individuals at a completely different price. Who has the right for such preferences? Today, a one-family house that has no gas or electricity for heating has the right for a so-called ‘fuel book’. According to this book, the individual gets 3.8 tonnes of pellets at the price of Br50 per tonne,” Vladimir Krech said.

Further purchases must be made at the standard price of Br200 per tonne. To heat a 100-square-meter house, approximately 4.5 tonnes of pellets are needed per season, totaling Br300. The price difference is covered by regional budgets. It is important to note that special equipment is required for using pellets. They cannot be burned in regular boilers or stoves, as their calorific value is 2.5 times higher than that of firewood. But pellet burning is an automated process. If you have a solid fuel boiler, it can be upgraded using a pellet burner.

“You load a certain amount of pellets into the bunker, and for nearly a week (depending on the bunker’s capacity) you do not need to enter the boiler room. You simply monitor the boiler’s operation and heat output through an app. It does not require constant ash cleaning: depending on pellet quality, the boiler should be cleaned perhaps once a week or even once a month,” Vladimir Krech stated.

What incentives have been provided to increase pellet consumption?

On 30 December 2024, the president signed a decree providing 40% reimbursement (up to 120 base amounts) for individuals purchasing boiler equipment made in Belarus or in the Eurasian Economic Union.

“We are already seeing progress in this area. Over this period, household consumption has increased significantly. The figures are not yet where we want them to be. But we remember the experience of our neighbors and understand that transitioning to this type of fuel is a gradual process,” Vladimir Krech said. “The government’s incentives will show results, and in a few years, pellet consumption will increase not just several times, but tens of times, primarily among households.”

Enterprises are installing special pellet boilers or adding pellets into existing systems. Last year, nearly 7,000 tonnes of this fuel were used in the energy system. This year, consumption is expected to increase by 1,500 tonnes. Major investment projects are underway at the Minsk CHPP 5, the Shabany heating plant, and the Baranovichi CHPP. Thanks to energy infrastructure modernization, Belarus' pellet consumption is expected to reach 62,000 tonnes per year.