This plant was set up in Minsk almost 80 years ago, after the war. Its products are known in the post-Soviet countries. Over the years, the plant experienced both incredible ups and very unpleasant downs, but Aleksandr Lukashenko still calls it the face of the Belarusian machine-building industry. Have you guessed what enterprise will be featured in this episode? We will tell you about AIST bicycles and MINSK motorcycles that were honored with the USSR Quality Mark and dubbed "the monsters with a Slavic appeal" by the French. We will also explore how privatization almost destroyed the plant and why the Belarusian president wanted to keep this brand alive.

How did AIST bicycles come to be and where did Orlyonok and Lastochka go?

Let's start with a small historical overview. In December 1945, a train from Germany arrived at the Vostochnaya station in Minsk. It brought equipment and documentation of German enterprises to the Belarusian capital as reparations. The destroyed post-war Minsk launched the construction of a bicycle factory. A couple of years later, the plant produced its first bicycle B-16, an analogue of the popular German Brennabor bike. Ten years on, it began to produce the basic model B-114, which was the first in the series of well-known MINSK brand. Subsequently, it evolved into AIST.

At first Minsk bicycles were sold in the USSR (with sales demonstrating bonanza growth), in 1963 they went international. A few years later, the sales of bicycles totaled eight million units. In the 1950s, Belarus also launched the production of bicycles for teenagers Orlyonok and Lastochka. However, soon their production was transferred to Lithuania: the Minsk plant was preparing for serious changes.

What bike was the prototype of the first Belarusian motorcycle?

The first motorcycle in Minsk was produced in 1951 and was called M1A. Then why did it have "Moscow" on its tank? After the end of World War II, all equipment and documents were taken from the defeated Germany to Moscow as reparations. It was there that the production began initially. As the Minsk plant picked up steam, the Soviet government decided to move motorcycle production here.

The prototype was the German DKW RT125 model, which had been in service with the Wehrmacht since 1941. It was so successful that it began to be copied en masse around the world. For example, Yamaha and Kawasaki started with a copy of the RT125. Similar motorcycles were featured in the Harley-Davidson line-ups. We will jump ahead and say that in the 1980s Yamaha and Minsk were rumored to go into partnership to launch a licensed production of Japanese motorcycles in Minsk. A separate production building was reported to be built, but the collapse of the Soviet Union dashed all hopes and aspirations.

‘Iron buffalo’ and ‘Slavic monster’. Why are Minsk motorcycles loved all over the world?

The motorcycle MINSK 3.111 rolled off the production line in the 1970s. It stood out for its modern and fashionable design. The speed was at a solid 95km/h. The motorcycle also had a low and high beam switch and a turn signal. This bike received the USS Quality Mark.

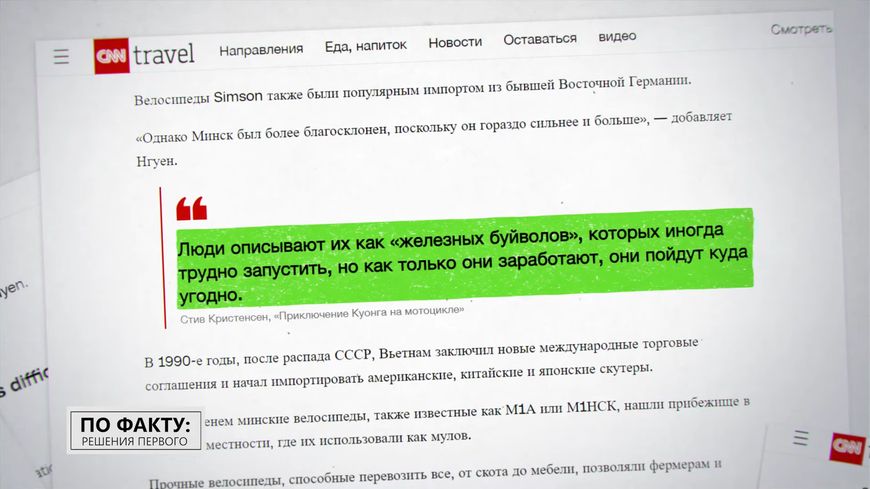

The geography of the export of the motorcycles was really impressive: from Brazil to Egypt, from Cuba to Mongolia. These motorcycles could also be spotted on the roads of European countries such as the UK, Germany, France or Czechoslovakia. In Vietnam, Belarusian motorcycles even had their own fan club and were called "iron buffalo".

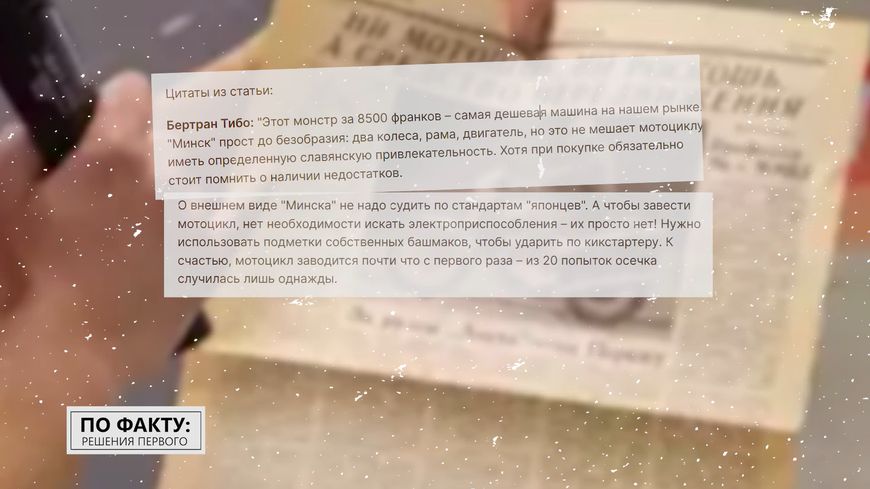

This is what a French journalist wrote about MINSK motorcycles: "This monster is the cheapest motorcycle on our market. MINSK is as simple as it can get: two wheels, a frame, an engine, but it does have a certain Slavic appeal. I was driving the MINSK motorcycle to commute to work every morning for two weeks at a speed of 93km/h and I proved that it was a great way to get to work. Bypassing a Mercedes stuck in a traffic jam, I would wonder how many MINSK motorcycles I could buy for the same money.”

How did AIST bicycles come to be and where did Orlyonok and Lastochka go?

Let's start with a small historical overview. In December 1945, a train from Germany arrived at the Vostochnaya station in Minsk. It brought equipment and documentation of German enterprises to the Belarusian capital as reparations. The destroyed post-war Minsk launched the construction of a bicycle factory. A couple of years later, the plant produced its first bicycle B-16, an analogue of the popular German Brennabor bike. Ten years on, it began to produce the basic model B-114, which was the first in the series of well-known MINSK brand. Subsequently, it evolved into AIST.

At first Minsk bicycles were sold in the USSR (with sales demonstrating bonanza growth), in 1963 they went international. A few years later, the sales of bicycles totaled eight million units. In the 1950s, Belarus also launched the production of bicycles for teenagers Orlyonok and Lastochka. However, soon their production was transferred to Lithuania: the Minsk plant was preparing for serious changes.

What bike was the prototype of the first Belarusian motorcycle?

The first motorcycle in Minsk was produced in 1951 and was called M1A. Then why did it have "Moscow" on its tank? After the end of World War II, all equipment and documents were taken from the defeated Germany to Moscow as reparations. It was there that the production began initially. As the Minsk plant picked up steam, the Soviet government decided to move motorcycle production here.

The prototype was the German DKW RT125 model, which had been in service with the Wehrmacht since 1941. It was so successful that it began to be copied en masse around the world. For example, Yamaha and Kawasaki started with a copy of the RT125. Similar motorcycles were featured in the Harley-Davidson line-ups. We will jump ahead and say that in the 1980s Yamaha and Minsk were rumored to go into partnership to launch a licensed production of Japanese motorcycles in Minsk. A separate production building was reported to be built, but the collapse of the Soviet Union dashed all hopes and aspirations.

‘Iron buffalo’ and ‘Slavic monster’. Why are Minsk motorcycles loved all over the world?

The motorcycle MINSK 3.111 rolled off the production line in the 1970s. It stood out for its modern and fashionable design. The speed was at a solid 95km/h. The motorcycle also had a low and high beam switch and a turn signal. This bike received the USS Quality Mark.

The geography of the export of the motorcycles was really impressive: from Brazil to Egypt, from Cuba to Mongolia. These motorcycles could also be spotted on the roads of European countries such as the UK, Germany, France or Czechoslovakia. In Vietnam, Belarusian motorcycles even had their own fan club and were called "iron buffalo".

This is what a French journalist wrote about MINSK motorcycles: "This monster is the cheapest motorcycle on our market. MINSK is as simple as it can get: two wheels, a frame, an engine, but it does have a certain Slavic appeal. I was driving the MINSK motorcycle to commute to work every morning for two weeks at a speed of 93km/h and I proved that it was a great way to get to work. Bypassing a Mercedes stuck in a traffic jam, I would wonder how many MINSK motorcycles I could buy for the same money.”

The plant in the 1990s

The company faced a number of challenges in its recent history. The collapse of the Soviet Union and subsequent disruption of long-standing contacts could not but affect its operations.

The company faced a number of challenges in its recent history. The collapse of the Soviet Union and subsequent disruption of long-standing contacts could not but affect its operations.

"We assembled strollers and miscellaneous substandard items. The collapse of the Soviet Union dealt us a heavy blow. Wages were delayed for two or three months and were below the subsistence level. Downtime could last from three days a week to half a month. When the president visited us for the first time, people were in desperate need of work. We were struggling. We had a very serious conversation back then. When the government stepped in, things started to change for the better. Wages are paid regularly, there is no downtime. We are optimistic about the future. We used to have a very small assortment: two or three types of bicycles, four at most. And now we produce about a hundred of them,” Vladimir Bukaty, mechanical assembly mechanic, said.

"The plant was in dire straits. There were disruptions of electricity and heat. We took to the streets to demand wages and heat. Now we are very glad to have this workshop and comfortable working conditions,” Nina Mikhalitsyna, mechanic for mechanical assembly works, said.

According to the woman, her entire family ride Belarus-made bicycles: “My husband and I, as well as our children and grandchildren ride only AIST [Stork] bicycles. We also have a mountain bike and simple bicycles. I am sure about the quality of our bicycles as I know how they are assembled. I want our 'Stork' to 'fly around' Belarus and everywhere.”

Privatization going wrong

After the collapse of the Soviet Union, the enterprise was privatized and transferred to the municipal authorities. But the situation at the plant only got worse. In fact, the labor collective took over the responsibility for the enterprise, but they never became its owners.

The output dropped, exports decreased multiple times. Warehouse inventories were snowballing. It took the government billions of rubles to turn the company around. Aleksandr Lukashenko emphasized that the state cannot leave the plant to the mercy of fate, because it is one of the country's industry flagships. Moreover, its products - both motorcycles and bicycles - are in demand in Belarus and abroad.

"The enterprise must and will work", the president said at a meeting in 2005.

A couple of years later, the government sold the enterprise to an Austrian company led by a Belarusian businessman. He promised to invest tens of millions of euros in the enterprise, but reduced the output “down to the volumes determined by the market.” Later it was revealed that the enterprise derived its income from renting out its premises, and that the machines were sold abroad at the price of scrap metal.

The government takes tough action against fraud. Yet, the company could not avoid bankruptcy. But the government managed to save the brand and production.

“I will never ever give up on this brand or let it vanish. We will turn it into a very advanced enterprise. I am petrified by the thought that we might lose this brand. I want my people, my workers to have jobs, make money and feed their children,” Aleksandr Lukashenko told journalists during subbotnik in 2012.

MotoVelo now

At the meeting to discuss domestic production of motorcycles and bicycles on 16 February 2021 the president demanded a clear-cut development plan for the company.

“It would be absolutely wrong to assume that we will sell this enterprise, privatize it, shut it down or reduce it to a bicycle spokes manufacturer, while the investor will transfer all competencies somewhere to Italy, Russia or China. Enterprises like MAZ, BelAZ, MTZ, Gomselmash are the calling card of the country's mechanical engineering, its top brands. MotoVelo Plant is among them. Therefore, we cannot let it go under. The idea of tearing the enterprise into pieces and then distributing these pieces among banks (Belgazprombank, Alfa Bank and others) goes against the interests of the state. This amounts to the destruction of the enterprise,” the president said.

It was decided to turn vacant premises of the bankrupt enterprise to a technopark. Various high-tech production facilities are to open here. MotoVelo Plant will be a keynote resident company in the technopark. Reconstruction and large-scale modernization are underway. Some of the equipment has already been installed. The main emphasis is on increasing localization. This is the number one task from the president. Assembly production is, of course, a convenient practice. Get spare parts, put them together and the product is ready. Yet, as Aleksandr Lukashenko stressed, the best option is to produce spare parts domestically.

"The plant was in dire straits. There were disruptions of electricity and heat. We took to the streets to demand wages and heat. Now we are very glad to have this workshop and comfortable working conditions,” Nina Mikhalitsyna, mechanic for mechanical assembly works, said.

According to the woman, her entire family ride Belarus-made bicycles: “My husband and I, as well as our children and grandchildren ride only AIST [Stork] bicycles. We also have a mountain bike and simple bicycles. I am sure about the quality of our bicycles as I know how they are assembled. I want our 'Stork' to 'fly around' Belarus and everywhere.”

Privatization going wrong

After the collapse of the Soviet Union, the enterprise was privatized and transferred to the municipal authorities. But the situation at the plant only got worse. In fact, the labor collective took over the responsibility for the enterprise, but they never became its owners.

The output dropped, exports decreased multiple times. Warehouse inventories were snowballing. It took the government billions of rubles to turn the company around. Aleksandr Lukashenko emphasized that the state cannot leave the plant to the mercy of fate, because it is one of the country's industry flagships. Moreover, its products - both motorcycles and bicycles - are in demand in Belarus and abroad.

"The enterprise must and will work", the president said at a meeting in 2005.

A couple of years later, the government sold the enterprise to an Austrian company led by a Belarusian businessman. He promised to invest tens of millions of euros in the enterprise, but reduced the output “down to the volumes determined by the market.” Later it was revealed that the enterprise derived its income from renting out its premises, and that the machines were sold abroad at the price of scrap metal.

The government takes tough action against fraud. Yet, the company could not avoid bankruptcy. But the government managed to save the brand and production.

“I will never ever give up on this brand or let it vanish. We will turn it into a very advanced enterprise. I am petrified by the thought that we might lose this brand. I want my people, my workers to have jobs, make money and feed their children,” Aleksandr Lukashenko told journalists during subbotnik in 2012.

MotoVelo now

At the meeting to discuss domestic production of motorcycles and bicycles on 16 February 2021 the president demanded a clear-cut development plan for the company.

“It would be absolutely wrong to assume that we will sell this enterprise, privatize it, shut it down or reduce it to a bicycle spokes manufacturer, while the investor will transfer all competencies somewhere to Italy, Russia or China. Enterprises like MAZ, BelAZ, MTZ, Gomselmash are the calling card of the country's mechanical engineering, its top brands. MotoVelo Plant is among them. Therefore, we cannot let it go under. The idea of tearing the enterprise into pieces and then distributing these pieces among banks (Belgazprombank, Alfa Bank and others) goes against the interests of the state. This amounts to the destruction of the enterprise,” the president said.

It was decided to turn vacant premises of the bankrupt enterprise to a technopark. Various high-tech production facilities are to open here. MotoVelo Plant will be a keynote resident company in the technopark. Reconstruction and large-scale modernization are underway. Some of the equipment has already been installed. The main emphasis is on increasing localization. This is the number one task from the president. Assembly production is, of course, a convenient practice. Get spare parts, put them together and the product is ready. Yet, as Aleksandr Lukashenko stressed, the best option is to produce spare parts domestically.

“New equipment is being purchased and installed. Some of it has already been put into operation, for example, in the frame kit shop, where frames for city bikes are manufactured. The localization level reaches 72%,” Director of MotoVelo Plant Sergei Manko said.

Special attention is paid to the localization level in motorcycle production. For example, the MINSK D4 125 model features 28 component parts produced in Belarus. Thus, the rear view mirror is made by Universal Bobruisk, the instrument panel by Vitebsk Electrical Instruments Plant, the front headlight, turn signals and rear fairings by Amkodor-Belvar, the seat by BELAVTOMAZ Holding Company,

“We also plan to launch the production of the frame this year. The localization level for this model will reach 70%, taking into account the internal combustion engine: Minsk Motor Plant is working on it this year,” Sergei Manko said. “As part of modernization, we have launched a line to make the frame for the AIST245 bicycle. The frame, shields, and pedals are made in Belarus. The seat is also Belarus-made. This bicycle features as many Belarusian components as possible. Previously, this model was only assembled here. Today we produce the frame, fork, shields, luggage rack, seat, disks, and wheels”

By the way, the MotoVelo Plant director rides a domestic bike - AIST Tracker. It is a reliable city bike with wider and smaller wheels (26-inch rim instead of 28-inch standard).

What novelties is MotoVelo Plant working on?

The plant has recently developed a new transport vehicle - an electric motorbike. It is an urban-style electric bicycle on motorcycle wheels. The idea was adopted from Chinese manufacturers, Sergei Manko said. The design has been fully developed in Belarus.

“We have designed the bike, made the frame. The bike is undergoing certification trials. If everything goes well, it is likely to go on sale next year,” the MotoVelo Plant director said.

The battery is removable and can be charged from the mains. It offers 40km range on one charge or an opportunity to pedal.

No license is required to ride the vehicle, Sergei Manko said. “This is an electric motorbike - it has a speed limit of up to 25 km per hour,” he added.

MotoVelo Plant also produces electric scooters for teenagers and adults. Their production was launched in late 2023. 300 scooters have been made so far. Part of them has been sold abroad.

Today the AIST bicycle line features more than 130 models of children's, hardtail, folding, city, and highway bicycles. The plant also produces ready-made electric bicycles (nine models), offers bike tool kits for almost any bicycle. The company plans to reach an annual output of about 250,000 bicycles by the end of 2025.

The production site of MINSK motorcycles is the largest one in Eastern Europe. The company produces motorcycles, scooters and mopeds, enduro motorcycles. The plant applies modern technologies and works in cooperation with world manufacturers.

President’s main requirement

"I rode a bicycle when a child. Now I do too. I am President but I still like to take a bike ride. When there is no snow and the asphalt is wet (and you can't roller ski), I ride a bike. If we had a true dictatorship, I would ban motor vehicles in Minsk and allow only bicycles. That would be great. But this is impossible. I am your supporter. I am an ardent supporter of the bicycle production in the country and cycling sport. Everyone can afford it. Cycling is the best thing for health. Better than football, hockey. A bicycle is very good for the heart,” Aleksandr Lukashenko said during a visit to the plant in March 2021.

The president recalled that different kinds of ways were tried to develop the motorcycle production, including by selling it to private businesses.

“We tried everything. We have come to the conclusion that no private company is up to the task. There are very few good private companies willing to work for people. We need to produce component and spare parts locally. It is a huge amount of money, huge expenses; we have to bring them from abroad, and then take the finished product back to that market. We have to produce as much as we can here. We need to bring MotoVelo Plant back to its Soviet glory within the next five years,” the head of state said.

The story of MotoVelo Plant deserves to be made into a Hollywood movie. We cannot wait for our filmmakers to tap into the national industry flagships and the famous brands of Belarus, which have long become immortal classics. You must agree that their story is really captivating.