Light industry enterprises in Belarus were worst hit by the collapse of the Soviet Union. They were left without a raw material base, sales markets or experience of working in a competitive environment. Factories were in dire need of more efficient equipment. From year to year, the problems snowballed. It took time to rectify the situation. Today the Belarusian light industry, once known throughout the USSR and far beyond its borders, has gained its former glory. In this episode of BelTA’s YouTube project “After the Fact: Lukashenko’s Decisions” we will tell you why Belarusian clothes for babies received the USSR Quality Mark and why this manufacture is unique today. How did Belarusian government get the local garment enterprises out of the wood? Why did Aleksandr Lukashenko call the light industry a difficult business? We will also tell you what apparel manufacturer the president prefers and where "the president’s merch" is made. As they say, let’s put facts on the table.

What is Svitanak factory famous for?

The light industry of Belarus comprises almost 2,000 organizations with a total workforce of about 80,000. It produces textiles, clothing, leather and fur products. Though Belarus is not a major world's light industry manufacturer, it still holds a 20% share in the CIS market. All in all, Belarusian products are supplied to more than 70 countries.

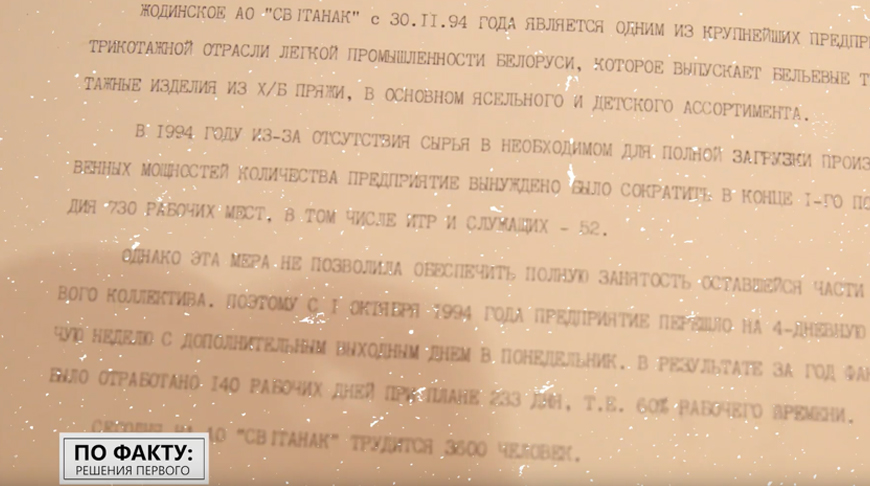

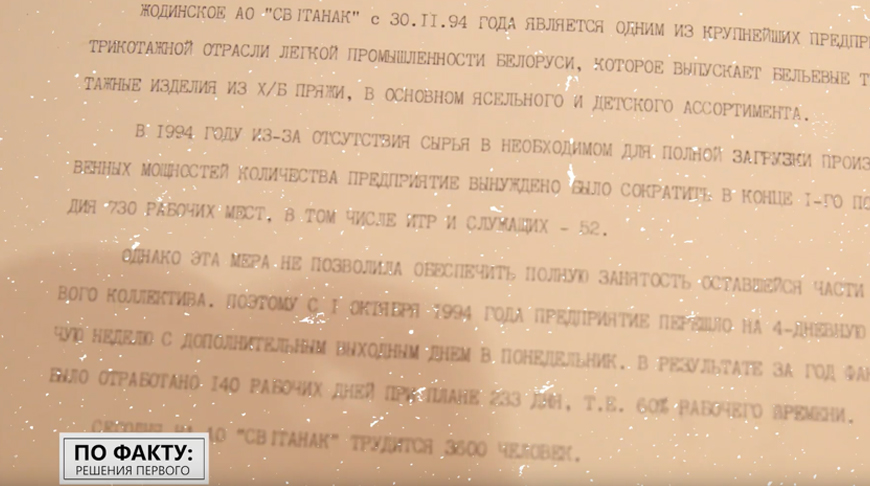

In 1994, due to the lack of raw materials, the company was forced to lay off 730 people. However, this measure did not save the situation and the remaining workforce still did not have enough work. As a result, the factory switched to a four-day working week.

The light industry of Belarus comprises almost 2,000 organizations with a total workforce of about 80,000. It produces textiles, clothing, leather and fur products. Though Belarus is not a major world's light industry manufacturer, it still holds a 20% share in the CIS market. All in all, Belarusian products are supplied to more than 70 countries.

We will narrate the history of this industry using the example of Svitanak factory, the country’s largest manufacturer. The history of this enterprise began in 1975, when the Zhodino sewing and knitting factory was established as a branch of the Minsk Production Association Progress. Two years later, the Zhodino factory became famous not only in Belarus.

Despite the successes, it was clear that the company was capable of much more. However, the development was hampered by dependence on imported materials. Therefore, in 1981, the construction of a knitted fabric factory began in Zhodino. The first complex was put into operation in 1985, and a year later the second complex of dyeing and finishing was commissioned. With new capacities, the factory was transformed into an independent business entity - Zhodino Production Sewing and Knitting Association. In 1991, it received its current name Svitanak. Ambitious plans were disrupted by an event that made waves throughout the world - the collapse of the Soviet Union.

How did the Belarusian light industry tackle the crisis?

"Today, we have work, stability, social security benefits. The 1990s was a very difficult time. We worked a four-day week. On weekends we shuttled to different places to sell our goods. I went to Russia: they loved our cotton goods,” Valentina Mashkovich recalled. Belarusian knitwear is known for high quality, good tailoring and fabrics. I have been retired for nine years, I am 64. But I continue working, I like my job. The conditions are good."

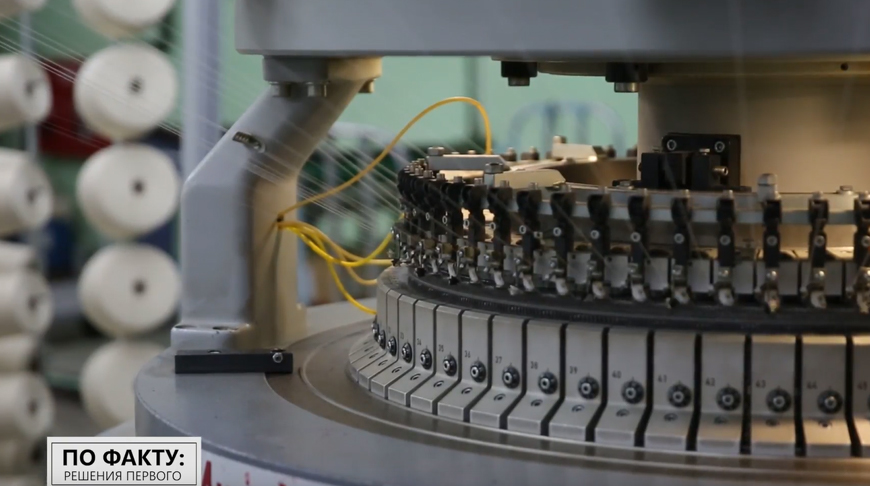

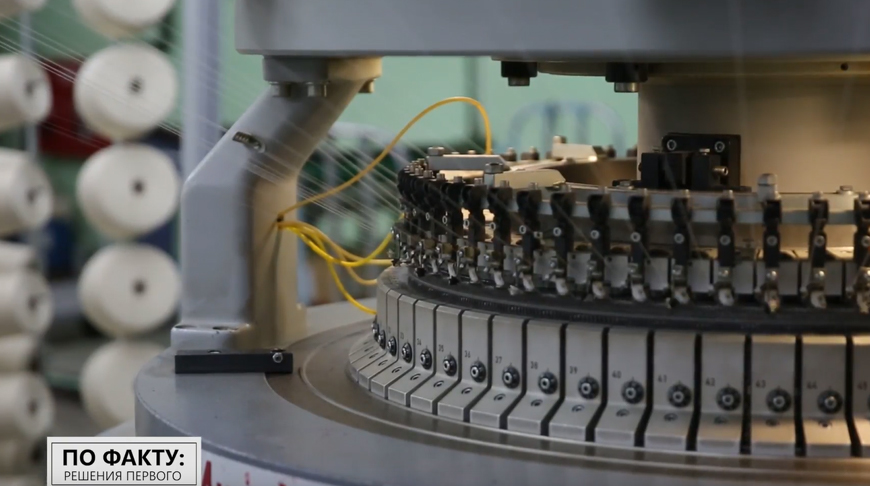

"We have been through all kinds of periods. There was a good time but things changed for the worse. We had downtimes. Sometimes we worked three or four days a week. We had interruptions in yarn supplies. Now there are no problems with yarn, and the equipment is more productive. Earlier I did 60kg per shift. Now it is 120-130kg and even more. Equipment is advanced: compute-controlled. A computer will tell you if there is something wrong. If a thread is broken, then it even indicates which thread. We work full time. We have a lot of work. I have already reached retirement age, yet the company has a place for both me and the younger generation. This is a good thing,” Maria Babitskaya noted.

The government tried hard to help domestic factories stay afloat. In 2006-2007, Bellegprom Concern received financial support worth as much as Br80 billion. The industry, however, kept struggling, while the quality of goods still left much to be desired.

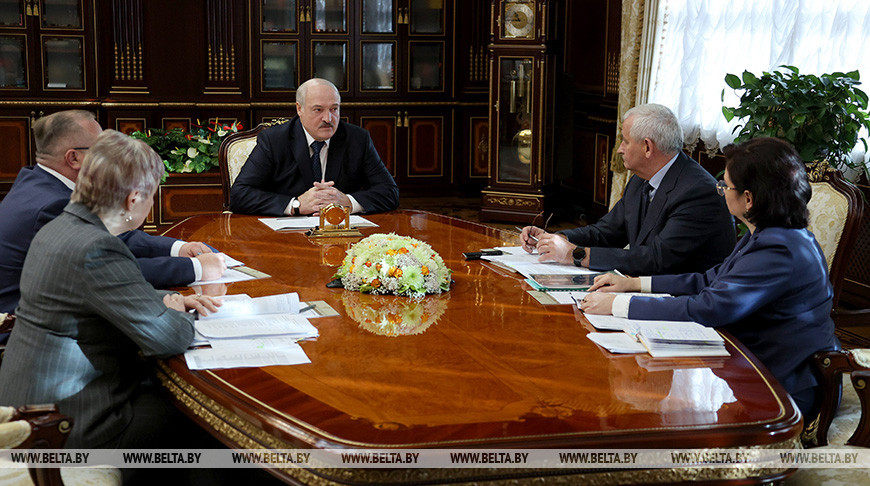

What did Lukashenko demand from the light industry?

The president decided to pay a visit to Svitanak to study the situation in the industry and outline possible development prospects. Why did Aleksandr Lukashenko decide to visit the factory which was doing relatively well? The head of state wondered why some did well and others struggled. He believed that the low return on the support was largely due to widespread mismanagement.

“Many of our directors are simply lazy. I have been monitoring several enterprises for some time, and those of them who took it up a notch, managed to get back in the groove. Now director knows how to make business. Director matters. If you take up the post, work. If you do not, leave. That's all,” the president said.

After the meeting held at the factory, Aleksandr Lukashenko emphasized that the industry should not manufacture for stock. The main task is to saturate the domestic market with quality Belarusian-made goods.

“I want you to give our people a choice. I want you to make clothes on par with foreign manufacturers. First of all, our people deserve it. Secondly, we have reached the point in our development when we can set such goals and fulfill them. We should be able to choose. Young men and women, young people should have a chance to dress like... I don't want to say “like people in the West” because the way they dress is ugly. But they have a huge choice. I want our people a decent choice of high-quality footwear and apparel. I don't want our people to go abroad and buy shoes and clothes there. All this should be made in our country, by our enterprises. I have one interest, the one of my constituents, my people,” the Belarusian leader said.

How children's wear became Svitanak’s business card

Today Svitanak is the only full-cycle light industry enterprise in Belarus. The manufacturing process covers fabric knitting, drafting, sewing and delivery of the finished product to the store.

In 1977 Svitanak was awarded the State Quality Mark of the USSR for its nursery line. Almost 50 years later, a similar clothing line can qualify for the Quality Mark of Belarus. It comes for a reason as the factory has always stuck to the “nothing but the best for children" philosophy.

“Svitanak pays close attention to its children’s line of clothing. Human life begins at birth, and every newborn needs to feel safe and loved. Our dedicated team of professionals makes garments that encapsulate our commitment to a healthier and safer world for little ones. Applying for the Quality Mark is not a walk in the park. It implies a lot of work. It is necessary to describe the properties of the product, prove that the product is of premium quality and meets all the requirements for nursery goods. We make products using velvet-like fabric. We are the only enterprise in the post-Soviet space that produces this type of fabric. That is why we have decided to apply for the Quality Mark with our velvet-like nursery line,” Yelena Zhdan, head of the technical control department, said.

Aleksandr Lukashenko keeps emphasizing that the crisis is a time of opportunities, and sanctions are a chance to win back the market. When Western companies leave Belarus, domestic producers should take their place.

“This opens up an opportunity for you to take this niche in Russia, our main market, and in the domestic market as well. Therefore, if you and other sectors, for example, agriculture, miss out on this opportunity, you are worthless. A crisis gives us a hard time, but it is a chance, it is an opportunity, first of all, for the light industry. We have everything in place. We have fabrics, sewing machines, qualified personnel, including technologists and managers and seamstresses and other specialists - we have everything necessary. Therefore, everything depends on us and our actions,” Aleksandr Lukashenko said as he heard out the report on the country’s light industry in October 2022.

What did Lukashenko demand from the light industry?

The president decided to pay a visit to Svitanak to study the situation in the industry and outline possible development prospects. Why did Aleksandr Lukashenko decide to visit the factory which was doing relatively well? The head of state wondered why some did well and others struggled. He believed that the low return on the support was largely due to widespread mismanagement.

“Many of our directors are simply lazy. I have been monitoring several enterprises for some time, and those of them who took it up a notch, managed to get back in the groove. Now director knows how to make business. Director matters. If you take up the post, work. If you do not, leave. That's all,” the president said.

After the meeting held at the factory, Aleksandr Lukashenko emphasized that the industry should not manufacture for stock. The main task is to saturate the domestic market with quality Belarusian-made goods.

“I want you to give our people a choice. I want you to make clothes on par with foreign manufacturers. First of all, our people deserve it. Secondly, we have reached the point in our development when we can set such goals and fulfill them. We should be able to choose. Young men and women, young people should have a chance to dress like... I don't want to say “like people in the West” because the way they dress is ugly. But they have a huge choice. I want our people a decent choice of high-quality footwear and apparel. I don't want our people to go abroad and buy shoes and clothes there. All this should be made in our country, by our enterprises. I have one interest, the one of my constituents, my people,” the Belarusian leader said.

How children's wear became Svitanak’s business card

Today Svitanak is the only full-cycle light industry enterprise in Belarus. The manufacturing process covers fabric knitting, drafting, sewing and delivery of the finished product to the store.

In 1977 Svitanak was awarded the State Quality Mark of the USSR for its nursery line. Almost 50 years later, a similar clothing line can qualify for the Quality Mark of Belarus. It comes for a reason as the factory has always stuck to the “nothing but the best for children" philosophy.

“Svitanak pays close attention to its children’s line of clothing. Human life begins at birth, and every newborn needs to feel safe and loved. Our dedicated team of professionals makes garments that encapsulate our commitment to a healthier and safer world for little ones. Applying for the Quality Mark is not a walk in the park. It implies a lot of work. It is necessary to describe the properties of the product, prove that the product is of premium quality and meets all the requirements for nursery goods. We make products using velvet-like fabric. We are the only enterprise in the post-Soviet space that produces this type of fabric. That is why we have decided to apply for the Quality Mark with our velvet-like nursery line,” Yelena Zhdan, head of the technical control department, said.

Aleksandr Lukashenko keeps emphasizing that the crisis is a time of opportunities, and sanctions are a chance to win back the market. When Western companies leave Belarus, domestic producers should take their place.

“This opens up an opportunity for you to take this niche in Russia, our main market, and in the domestic market as well. Therefore, if you and other sectors, for example, agriculture, miss out on this opportunity, you are worthless. A crisis gives us a hard time, but it is a chance, it is an opportunity, first of all, for the light industry. We have everything in place. We have fabrics, sewing machines, qualified personnel, including technologists and managers and seamstresses and other specialists - we have everything necessary. Therefore, everything depends on us and our actions,” Aleksandr Lukashenko said as he heard out the report on the country’s light industry in October 2022.

As soon as the opportunity came, Bellegprom Concern and Svitanak decided to take the advice of the head of state, or to be more precise, to fulfill his instructions. The children's multi-brand store Neposeda opened its doors in Minsk, replacing Polish brands. The store sells goods from about 40 Belarusian enterprises.

“The first store has been opened in Minsk. I think the project will grow and similar stores will open in other cities. This one in Minsk is doing quite well. We are keen to build on this success,” said Yelena Zhdan, head of the technical control department.

What kind of clothes does Belarusian President Aleksandr Lukashenko wear? During the October 2022 meeting, he said: “It is a pity to see some of our people still opting for imported clothing. Luckily, there are fewer of them today. Don’t we have our own clothing manufacturers? We all wear domestically-made clothes here, right? I can show you that I am wearing locally-made clothing.”

Where is “Merch of the First” made?

Another clothing line, “Merch of the First”, flies off the shelves. The collection includes T-shirts, hoodies and other products with quotes from Aleksandr Lukashenko. The collection was doing so well that the company started selling it outside Belarus in branded stores. Do you know what phrase of the president became the most popular? It is “Get undressed and work till you sweat”.

Yet, workers of the factory have another all-time favorite - “Don’t give away your loved one.” It can be interpreted in several ways, though it is about our Motherland. Yet, it can melt the heart of any girl.

Why did Svitanak have to change its export and production strategy?

To stay ahead of the curve, Svitanak is constantly evolving and improving its technology. Over the last decade alone, a significant part of the sewing, dyeing, finishing and knitting equipment was upgraded. Machines and devices from leading manufacturers have been installed, which makes it possible to produce more than 12 million items per year. These efforts did not go unnoticed.

“It was a tough time for all industries, including light industry, especially those enterprises that catered to the markets of European countries, Ukraine. The sales nosedived. Since Svitanak has been working hard to grow its exports in recent years, we had to reconsider our export strategy and find new ways to increase our sales to friendly nations, primarily, the Russian Federation. Thanks to our ability to recalibrate our export strategy within a short time, we see no decline in exports, we are on track to fulfill our tasks. We have enough orders to keep our workshops busy,” Svitanak Director Yuri Lukashevich said.

This year we have received the Quality Excellence Award of the government of the Republic of Belarus. This increased our chances to get the Quality Mark.

What else does the Zhodino factory have in store for customers? Svitanak is actively promoting its new business - production of sportswear. The company branched out into this line of business more than five years ago and it has very ambitious plans for it.

“Knitwear has always been the driver of Svitanak’s sales. We made a name for ourselves as a producer of cotton clothing. Yet, we are fully aware that competition in this segment is getting tougher. Therefore, we decided to tap into a new line of business - gymwear, sportswear and athleisure. This year we are completing one of the stages of an innovative project to launch the production of special knitted fabrics for sportswear. The share of this clothing in our output is increasing. This year we plan to make about a million items. We see that these products are a good sell. We have line-ups for schoolchildren and national sports teams (athletics, skiing and team sports),” Svitanak Director Yuri Lukashevich said.

There's one more thing we want to mention. The name “Svitanak” is translated from Belarusian as “dawn”, “sunrise”. Agree, it bears a special symbolism today.