News of the story

"After the Fact: Lukashenko’s Decisions"

The global baby food market is growing. According to various estimates, it can reach almost $135 billion by 2029. The reasons range from rising birth rates in developing countries to an increasing number of working mothers seeking alternatives to breastfeeding. There is one enterprise in Belarus that produces dry, liquid and pureed baby food. In this episode we will tell you where the Volkovysk company ships its products. Why can't you use the same line to make all kinds of baby formula powder? What kind of product did the president find hard to resist?

Visiting the Volkovysk-based Bellakt in June, Belarusian President Aleksandr Lukashenko delved into the issues that are currently relevant for the enterprise. Talking with the team, the head of state asked about all aspects of baby food production. He noted that this industry is very important for the country today.

Free baby food in the USSR was dispensed by prescription in the so-called dairy kitchens. Mothers got milk, kefir, cottage cheese, adapted milk mixtures, juices, vegetable and fruit purees, porridge. The establishment of the new industry was supervised personally by General Secretary Leonid Brezhnev. The USSR built three twin plants. Volkovysk was chosen the venue for a dairy and baby food canning plant. It supplied products to Moscow, Leningrad, Belarus, the Baltic republics and Central Asian countries. Now boxes and cans marked with the Bellakt label are shipped to even more countries.

When asked by the president about the export, the employees noted that baby food certification is a very tough process, as baby food is a demanding product. At the moment, the company is getting its products certified for export to 7 countries. Baby food in tins will be exported to 15 more markets. The share of baby food is growing from year to year. Belarus supplies baby food to 11 countries. Getting into the markets of other countries is not easy. There are lots of specific requirements, even to packaging. For example, countries with hot climates prefer a tin can, said Ivan Lupish, Deputy Director General for Commercial Affairs at Bellakt.

“Before we enter a new market, we thoroughly study this country’s laws. We conduct market research and competitive analysis. It helps us better understand what products will sell well there and what products are compliant with local laws. After that we start looking for a partner in order to get registered together. We finalize the layouts if necessary, localize packaging and start deliveries,” Ivan Lupish said.

According to him, the main sales markets are Russia, Uzbekistan, Syria, and Kazakhstan. The company is expanding to Southeast Asia and the Arab world. For the latter, the enterprise has obtained a halal certificate. The company is actively penetrating the African market and increasing exports to Zimbabwe.

“The company passed the audit by the Ministry of Lands, Agriculture, Fisheries, Water and Rural Development of Zimbabwe last year. We obtained the necessary certificate. The next step was getting our products tested in Zimbabwean laboratories with the help of our partner. The testing outcomes were positive. Work is currently underway to adapt and supply products to the Zimbabwean market,” Ivan Lupish said.

In 2006, a presidential decree extended the Children of Belarus program. As part of the program, assistance was provided to the country’s only baby food manufacturer.

First Deputy Director General at Bellakt Tatyana Gorkavik recalled that in 2014 the enterprise increased production capacities in line with the Children of Belarus program approved by the president.

“We branched out into the production of liquid and pureed baby food. Our enterprise is constantly evolving and rapidly growing. Modernization is a continuous process at our company. We regularly upgrade equipment and refresh the product offering,” she said.

The company produces several types of baby food: for healthy babies and for babies with special dietary needs. The latter is particularly important. This lineup includes three products, said Natalya Karach, Head of the Children's and Dietary Nutrition Department at Bellakt.

“Bellakt PREActive is designed for underweight and premature babies. Bellakt Antireflux Active is meant for children suffering from regurgitation and other gastrointestinal disorders. Bellakt BL Active was developed for children, including infants, with primary and secondary lactase deficiency. I would like to highlight our new offering. This product is sold under the trademark Sam-Nyam. We began developing it last year. This product is designed for children from one year old. This product is meant for two categories of children with special dietary needs. The first are picky eaters; these are children who do not eat enough. And the second type includes those who have protein-energy undernutrition,” Natalya Karach said.

She added that developing a formula is a complex and meticulous process. It requires scientific data, research, and effort. Innovations and trends must be studied. The company has established a specialized baby food department. It features a medical marketing sector.

“This sector includes practicing doctors, pediatricians, neonatologists, candidates of medical sciences, and associate professors. Each has their own role. There are doctors who are directly involved in developing the baby food line. They conduct research, offer guidance, and give advice,” Natalya Karach, Head of the Children's and Dietary Nutrition Department at Bellakt, said.

Baby food safety standards are pretty much the same all over the world. This pertains to microbiological and toxicological requirements. However, there are differences in details, mainly in feed composition.

“Differences may lie in certain components, as different countries have varying physiological requirements for infant nutrition. For example, in China, baby food is regulated by GB standards, and the content of docosahexaenoic acid, derived from fish oil, is twice as high as in the European Union, Belarus, and Russia,” said Tatyana Novikova, Chief Technologist at Bellakt.

Dairy products for child nutrition must meet particularly strict requirements. At Volkovysk, even the raw materials are held to higher standards than those mandated by the Eurasian Economic Union.

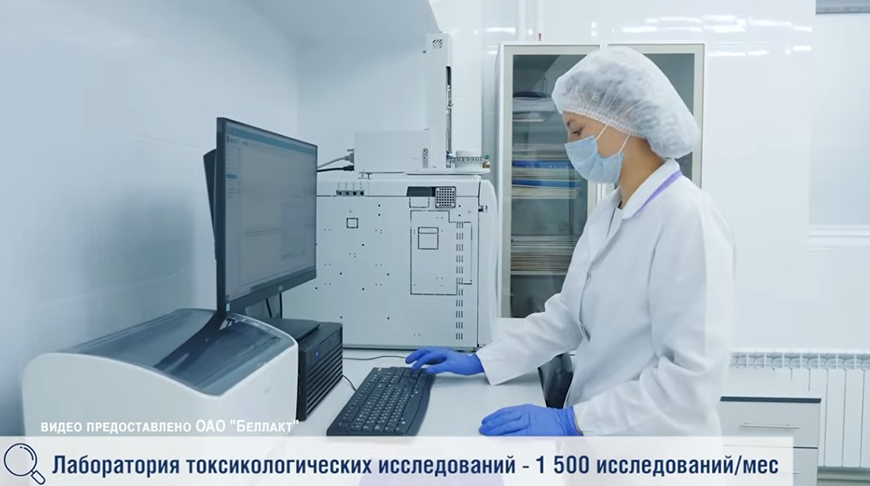

Tatyana Novikova said: “Only premium and extra-grade raw milk is used for these products. The highest quality in terms of microbiological and toxicological indicators. Additionally, baby foods are subject to strict regulations regarding heavy metals and pesticides. Compared to regular food for adults, the standards here are ten times stricter.”

According to the company’s workers, non-compliant ingredients cannot make their way to the company. There is a multi-tier control system.

The plant takes special pride in its team. Hiring a ‘ready-made’ specialist in this field is impossible; each employee is trained specifically for this unique production.

One of the Bellakt employees, who has been making the company’s products for 40 years, told the head of state that the company’s real pride was baby pasty food, which contains practically no sugar. She immediately offered Aleksandr Lukashenko to try a novelty, chocolate salami.

“This is our pride. No one else in Belarus makes it. It’s the taste of childhood. Our mothers used to make chocolate salami. This one is organic. Here, this one is sliced. Help yourself. We make it on an industrial scale, using specialized equipment,” the woman said.

“Don’t tempt me. I’ve got a sweet tooth!” the president joked and moved on to serious topics. On the agenda are hydrolysate, lactose milk. These import-substituting products can and should be produced in the country.

Chief Technologist at Bellakt Tatyana Novikova said: “The only thing we haven’t been able to produce is extensively hydrolyzed (a formula based on fully hydrolyzed whey protein) and amino acid formulas. But this is only because we have only one production site. We have just one line to manufacture baby food. It is used to dry both milk-based formulas and special formulas containing milk components. An extensively hydrolyzed formula requires an environment completely free of milk traces. We simply cannot guarantee that level of safety.”

Summing up the conversation on the topic of hydrolysate, Aleksandr Lukashenko indicated that if everything is economically calculated, then the project for the construction of a new production facility will be supported. “Whether you like it or not, every country must feed its people, especially, children,” said Aleksandr Lukashenko.

Later, in an interview with the After the Fact: Lukashenko’s Decisions” project, Tatyana Gorkavik noted “there are plans to construct a baby formula powder production facility in accordance with GMP standards. The need for construction has become urgent.”

“We should understand that this project cannot be implemented overnight: it will take years. This is why we need to start building now, and it must be a more advanced facility, fully compliant with GMP standards,” she said.

GMP is a set of guidelines for the pharmaceutical industry. It covers everything from the production process to the smallest details, such as how the baseboards meet the floor in a workshop. The new facility will not only be able to produce baby food, but also certain components that are currently being imported.

When the new production facility is launched, specialists will be able to manufacture formulas for children with severe allergies to cow’s milk proteins as well as products for infants recovering from surgery.

Every day, the enterprise processes 800 tonnes of milk. Raw materials come from Volkovysk District, Zelva District, Svisloch District, and Mosty District. Raw materials are sourced from 24 agricultural enterprises.