In recent years, the microelectronics industry has been a trending theme around the world. The U.S. and China are waging trade wars over chips. Belarus and Russia are discussing the projects to create new microcircuits at the level of the presidents. The West has been imposing sanctions on our enterprises for many years.

In this episode we will tell you why semiconductors are called "the new oil"; how the Belarusian Integral became one of the leaders in microelectronics; why production facilities should be cleaner than operating rooms; for what the Russian president is ready to pay Belarus any money. What the future holds for the main chip manufacturer in Belarus.

Microelectronics in Belarus

The history of Integral began 60 years ago. By that time, Belarus rose from ashes of the Great Patriotic War and became a machine-building and agrarian powerhouse. The country needed to move forward, to realize its technological and scientific potential.

Semiconductor Devices Plant was launched in Minsk in 1963. Thus began the official story of Integral. A few years later, another production facility was set up in the Belarusian capital - the Transistor plant. In 1971 they were merged into the country's first research and production association Integral. Very soon the company became the largest manufacturer of microelectronic products in Europe.

"In the past computers were large and could fit a room. With the development of aircraft construction and rocket engineering, the issue of miniature products took center stage. These enterprises were dispersed across the country: Riga, Tallinn, Vilnius, Chisinau, Georgia, and so on. As Integral grew and performed more and more complex tasks, we became comparable) in terms of output and number of factories with the largest associations of the Soviet Union. We were given the functions of the head office, said ValentinZolin, assistant to the Integral director general in 1981-2022.

However, with the collapse of the Soviet Union, all these enterprises did not withstand competition with European manufacturers. The post-Soviet states, having opened up to the West, were forced to close their factories and lose the unique competencies accumulated over decades. But that's a story for another day.

Areas of application of Integral products

Since Soviet times, Integral's products have been used in the defense and space industries that need microelectronics capable of withstanding extreme conditions.The Belarusian enterprise successfully coped with the tasks.

"What was Integral in its heyday, in the 1970s and 1980s? A huge team of more than 30,000 employees. We participated in various research programs, space being one of them. One of the banners that you see here was awarded for the participation in the Energia-Buran program. It was an analogue of the U.S. Shuttle program. Buran took off into space, completed several orbits around the Earth and landed in automatic mode at an airfield near Baikonur. Dozens, if not hundreds, of enterprises from all over the Soviet Union participated in the program. Integral was one of them,” said Vladimir Tsymbal, Chief Designer at the Science and Technology Center Belmicrosystems.

Today, few people will remember that Sekunda 2, the first electronic wristwatch in the USSR, was made by Integral.A little later Integral rolled out the Elektronika watch, a popular, reliable and very accurate watch. Even Japanese manufacturers were amazed by its technical specifications. This is not a joke. Thanks to the digital rate adjustment function, the Elektronika watch showed accurate time for the entire service life.

After cosmonaut Kovalenok went into space wearing this watch, it became obvious that the enterprise in Minsk produces watches capable of withstanding space payloads.

“I went once on a business trip to Moscow. I was summoned to the Ministry of Electronic Industry. At that time, we were implementing a very important project. Officials of the ministry told me that the ministry’s leadership had a high opinion of Integral. They would say if you want something done well and on time, then give this project to the Belarusians. They will never let you down,” Valentin Zolin noted.

Dire situation during the 1990s

The perestroika and then the collapse of the Soviet Union hit the enterprise hard. The transition from military to civilian economy left Integral practically without orders. Overnight, the enterprise went from being a top-notch company, a dream employer for everyone, to a cash-starved wreck."

Integral lost about 80% of the market and faced the prospect of a complete shutdown. Its workers took to the streets and demanded urgent measures from the country's leadership. Integral also appealed to the government for help.The overall situation at the enterprise could be described as “dire”, and the financial standing as “catastrophic”. But the Supreme Council left this appeal unanswered.

“The help came after the president’s first visit in 1995. This was probably one of his first visits to large industrial enterprises after taking office. He inspected workshops, met with the staff, answered questions. And the help we received soon afterwards was quite substantial,” Valentin Zolin said.

Back then, according to Aleksandr Lukashenko, he had to visit the workshops because of the mounting rumors about the restructuring and privatization of the enterprise, about layoffs and impending unemployment. Aleksandr Lukashenko emphasized: “Supporting people, labor collectives is the sacred duty of the authorities.”

In 2000 alone, the government allocated Br92 billion in bailout for industrial enterprises. It helped save struggling enterprises and turn them around. Enterprises began to generate revenues; the amount of taxes they paid to the budget increased several dozen times over the period when they received the bailout.

What Lukashenko said about the Integral

In the late 1990s, experts had no doubt that Integral would sooner or later go under or be bought by competitors.

Indeed, such a probability was high. The well-known American company Motorola lent a helping hand to the Belarusian manufacturer. But it turned out later that this “help” had an agenda.

The Americans’ plans were simple: to weasel their way into the company, buy out the enterprise, and eliminate the competitor. The Belarusian authorities uncovered these designs just in time.

Five years later, in March 2001, the president visited Integral again and saw for himself that over the years the company had taken 10 steps forward. Thus, the output increased more than 5 times in comparable prices over 1990, and the share of exports exceeded 60%. In 1991 it was only a tenth of a percent.

“I flatly refused to destroy the established system, including at the company [in the 1990s]. The task was to restore production, protect people, etc. We saved the enterprise; we did not cut it into pieces or sell it. We turned the company around and now it sells its products all over the former Soviet Union. This is the foundation and the future of any economy. This is the intellectual core of the nation,” Aleksandr Lukashenko told reporters as he visited the company.

Yet, the president warned that the government would not endlessly sustain poorly performing companies.

When a company is back in the black, it should rely on its own resources, operate in line with economic laws, generate profit and grow amidst competition.

Therefore, in 2009, when the project to launch submicron production at Integral was hanging in the balance, the head of state minced no words saying: money was allocated, deadlines were set, so those who botched the project would be held accountable. Integral should be the pride of the country and no excuses would be accepted.

During the visit to Planar in 2023, Aleksandr Lukashenko recalled what could have happened to Belarus’ microelectronics industry: “I remember the time when they were pushing me to sell, to close these enterprises. They said they would buy, import everything from the West. Thank God, the country has preserved Planar, Integral, BelOMO, Horizont, and Vitebsk Monolith, though things were very difficult sometimes. Most importantly, we preserved the research infrastructure of this science-intensive industry. 30 years have passed. What do we see? In the fight for the new world order, technology plays a decisive role. The one who has it will be able to survive and establish their own rules of the game in the future. The so-called civilized, democratic Western world will not hesitate for a second to use technology as a leverage, to impose sanctions trying to subjugate the undesirable states that compete with them."

Integral today

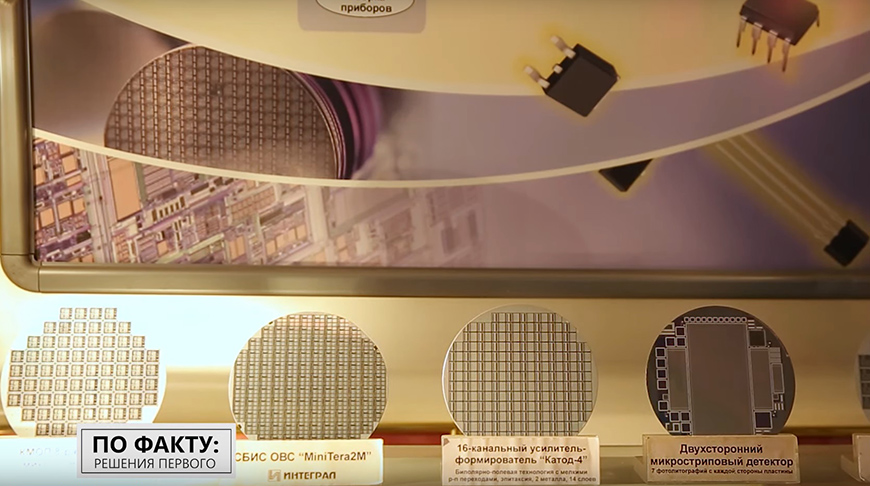

Today Integral is the largest manufacturer of integrated circuits and semiconductor devices in Central and Eastern Europe. Its chips are used in weapons, spacecrafts, and satellites to help them see remote corners of our planet. The holding companyruns production sites in Minsk, Molodechno, Brest, Pinsk and Gomel. Microelectronics is one of the most sophisticated, but extremely popular fields of work. The company’s product portfolio is impressive. It includes more than 2,500 types of integrated circuits, 500 types of semiconductor devices, 200 types of liquid crystal indicators and modules, 150 types of electronic products. Imagine a microcircuit that can withstand the temperature of -60°C. It retains its characteristics even if it is suddenly placed in another environment, for example in a place with the temperature of +120°C. Isn’t this impressive?

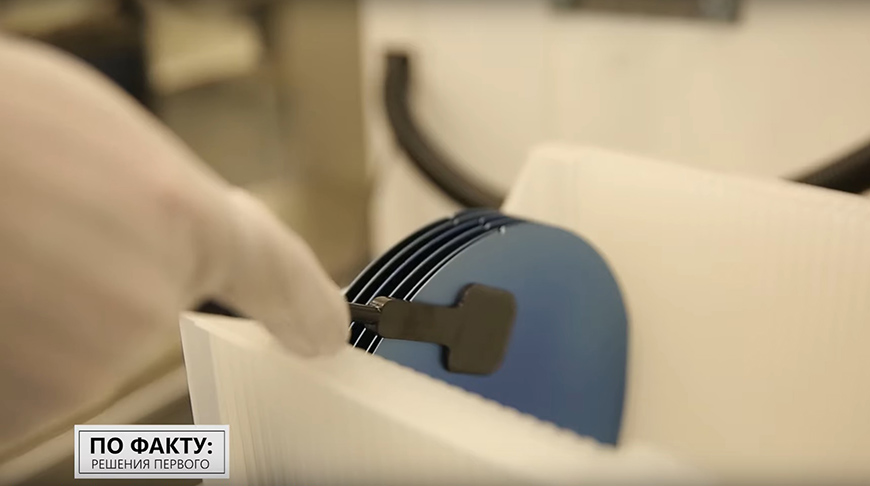

“Microelectronic products can be made from various materials. Integral works with silicon. Silicon ingots are obtained from quartz sand. Quartz makes up 27.6%of the Earth's crust. We useingots with diameters of 100, 150, and 200 millimeters. During the preparatory stage, silicon ingots are cut into wafers, then ground and polished until they resemble a mirror. After that, they are sent to Minsk where they go through a full production cycle to become integrated microcircuits and semiconductor devices,” Chief Assistant to Director General Ruslan Bogoslav said.

Special conditions have been created in production premises. The company spends several hundred thousand dollars every month to maintain the cleanrooms. And you can only work here in special protective gear - so that not a single speck of dust gets into the air.

“This is Class 10 cleanroom, i.e. here the maximum number of particles with a diameter of 0.5 micrometers per cubic meter is 10. To put this in perspective, one micron is one-sixth the width of a human hair,” Deputy Chief for Production Anton Karpievich said.

Sergei Borzdov, Leading Electronics Engineer recalled: “The work was much harder in the 1980s. There was a box in front of you, with some buttons and toggle switches on it, and if something broke down, you could not figure out how to fix it. The equipment had no diagnostic systems. But today, if it breaks, the computerized diagnostic system tells you which sensor failed. I really enjoy doing my work. I go to work with pleasure, because my job is not only to identify malfunctions.”

“I go to work with pleasure, because my job is not only to identify malfunctions. It is about both technology and creativity. If a component fails, it must be replaced. I do everything myself: I design, solder, debug, and write the software. I get a true thrill out of it. The top three things that make me happy are food, women and my work,” Sergei Borzdov said.

What projects is Integral working on today?

Silicon used to be the main material for semiconductor electronics. Its properties, however, limited the areas of its application. Over the past few decades, scientists had been searching for a new material to make a breakthrough. And they found it - gallium nitride - Gallium N.

“Gallium N is a technology currently evolving all over the world. This is where we have a chance to keep up with the rest of the planet. In silicon-based microelectronics we have fallen far behind. We may try to do some catch up. It is clear that we will not be able to break into the mass market. This would require huge investment and sales markets, which have long been divided. With Gallium N we have a great chance and we need to seize it. This is why a laboratory of new technologies and materials was set up in 2018. Gallium N was chosen as the priority area of work,” Deputy Director General - Chief Engineer Natalya Kovalchuk said.

Microchips are used everywhere today: processors in smartphones and computers, microcontrollers in washing machines, car engines, elevators and even modern light bulbs. In 2022 the global semiconductor market amounted to almost $600 billion, while the consumer electronics market exceeded $1 trillion. The oil market is estimated at just $350 billion. Semiconductors have already been dubbed “the new oil”.

“Integral is implementing two innovation and one investment projects. All the three projects are aimed at upgrading every manufacturing stage, from wafer-plate production and microchip design to assembly, testing and measurement of the final product. The ultimate goal of the projects is to launch the production of import-substituting goods, increase the enterprise's capacity and expand its technological capabilities,” Deputy Director General for Production Development and Support Maksim Maksimovich said.

On a global scale, Integral is a small company. To make it into the list of leaders it needs to inject tens of billions of US dollars in its production and personnel training. Is it worth the effort? The question is by no means rhetorical. After all, today Integral has everything in place to make money and grow.

Why did Belarus and Russia decide to invest in microelectronics?

In October 2022, while coordinating the appointment of a new head at Integral, Aleksandr Lukashenko said that he had discussed cooperation in microelectronics with his Russian counterpart.

“During the latest meeting the Russian president remarked they were ready to pay any price for microelectronic products. I have to admit that this sector deteriorated considerably in the post-Soviet space. Microelectronics is vital. Aircraft, missiles, high-precision weapons use them. Thank God, we have kept this enterprise going. We need to be well-versed in every single aspect of this industry. It needs a breakthrough, a major breakthrough. Belarus and Russia are going to invest heavily in this industry. Great opportunities are opening up for us: Belarus-Russia market, the market of post-Soviet countries. The products will sell everywhere if they are good. But competition is really tough. Thank God the competitors left our market. It means our products will be in demand. This is why we are going to take care of this industry together with Russia,” the head of state said.

In 2022 the head of state held a meeting to discuss the development of the microelectronic industry in the country. The meeting gave another impetus to Integral’s development. “The country has approved the microelectronic industry development program through 2030. There is also a roadmap for microelectronics production at Integral which has been agreed with the Russian partners. This roadmap serves as the basis for an investment project to start producing 150mm to 200mm crystal wafers. This project is of strategic importance. The project is import-substituting. The technologies and products to be made in the course of the project are in high demand among our partners,” Director General Andrei Buinevich said.

What Integral products deserve the State Quality Mark?

Back in 1972, many Integral products earned the USSR Quality Mark. Diodes, transistors, and two dozen models of wrist watches Elektronika were among them. What Integral products are worth the State Quality Mark of the Republic of Belarus?

“Our quality management system enables us to maintain the traditions that go way back to the Soviet Union and meet modern requirements. Currently, we are working to implement the roadmap that is tailored to the needs of the Russian market too. The enterprise also supplies large batches of integrated circuits to the markets of South-East Asia. We believe that any of these products can qualify for the State Quality Mark. The product warranty period of up to 15-20 years is a testimony to that,” Head of the Quality Management Coordinating Center Olga Guz said.

“National assets” is much more than a beautiful phrase for Belarusians. This notion embraces the enterprises the country takes pride in, the personnel appreciated and supported by the government, huge haul trucks and tiny microchips. Their present and future depends only on us.