What company do you think will be featured in this episode? Here are some clues. One of the stars in the Orion constellation was named in honor of this enterprise. Lukashenko was offered to move the Belarusian capital to the city that hosts the company. By the way, this plant was built in the Soviet years. It was built with the participation of Austria and Italy. In terms of area, the plant is larger than the Principality of Monaco and employs about every seventh resident of the city. In this episode of of BelTA’s YouTube project "After the Fact: Lukashenko’s Decisions”, we will tell you about the industry flagship - the steel pillar of Belarus. Are you intrigued?

History of metallurgy operations in Belarus

You have probably already guessed that this is Belarusian Steel Works (BMZ trademark). The history of the enterprise began relatively recently, in the 1980s. However, the foundry industry in Belarus goes back a longer way, to the times of the Polish-Lithuanian Commonwealth and the Russian Empire. This industry was founded by Joachim Khreptovich, the largest Belarusian landowner, the last Chancellor of the Grand Duchy of Lithuania, philosopher, reformer, poet and publicist. In 1780, he founded the first foundry in the country in one of his estates in the village of Vishnevo.

The products were in huge demand. However, with the death of Joachim Khreptovich, the foundry fell into neglect. The metallurgy hub moved to the village of Starinka in Slavgorod District. The estate was owned by Alexander Benckendorff, a representative of the famous noble family. The manufacture began to flourish thanks to a large-scale program for the construction of the Black Sea Fleet. It made anchors, chains and various metal fasteners. Later, it even produced steam engines. But over time, due to various reasons, this enterprise also fell into decline.

A new chapter in the history of Belarusian metallurgy began only a century later. In the spring of 1982 the ground was broken for a steel plant in the provincial Belarusian town of Zhlobin. Austrian and Italian specialists were involved in the construction. For the first time in the history of the domestic industry, foreign companies took part in the turnkey construction project. The Italian-Austrian alliance set up a European-type mini-plant near Minsk. Equipped with the latest technology, it was unmatched in the Soviet Union. The company got its name thanks to the first director – Derozhant Akopov. Initially, they planned to call it ZhlobinSteel Works. Only thanks to the persistence and persuasiveness of the director, the plant got the proud name ‘Belarusian’.

"The Soviet Union meant to build three plants: in Moldavia, Komsomolsk-on-Amur and in Belarus. Since Belarus is located in the center of Europe, the most advanced plant was built in Zhlobin. Here, all the technology and equipment were top of the line. We were lucky to get such a beautiful plant equipped with the latest technology. The city had an inflow of people. Everyone shared their experiences. They started families. The team was truly multinational. The place has grown into a beautiful city,” said Piotr Babkov one of BMZ old-timers, the head of Technological Equipment Repair Section.

Belarusian Steel Works had workers and engineers from different parts of the USSR. For example, Lyubov Gubina and her husband moved to Zhlobin from the Urals. She comes from a family of metallurgists. Lyubov Gubina’s great-great-great-grandfather worked for the Demidovs, the richest Russian entrepreneurial family. Over two centuries the Demidovs founded many Ural cities and built dozens of metallurgical plants.

Lyubov Gubina, veteran worker, head of the best labor dynasty of Belarus. "My mother was a metallurgist, and my husband's grandfather was a metallurgist. Until my retirement, I worked at the plant. My son also came to the plant and works here to this day. My daughter works here. My granddaughter (my son's daughter) works in one of the BMZ laboratories. My son-in-law also works here. My granddaughter's husband is a worker here too."

BMZ in the 1990s

But, no matter how modern, technologically advanced and sought-after Belarusian Steel Works was, in the 1990s it still could not escape the fate that befell the entire country with the collapse of the Soviet Union and the severance of economic ties with other post-Soviet republics. The lack of raw materials and orders slowly drove the company into a dead end. Its desolated workshops were taken over by some shady private firms. The inflation was sky high. As old-timers recall, they needed to bring bags to collect their wages.

“Inflation was rampant. It would eat up all our wages,” said Aleksandr Loskov, lathe operator at the Metallurgical Equipment Repair Shop. “The plant paid wages twice a month in addition to an advance payment. In other words, the wage was divided into three, and somehow we managed to hold out.”

According to him, the situation at the plant started to change after Aleksandr Lukashenko came to power.

“We voted for Aleksandr Grigorievich in the second round. Everyone was tired of the old leadership, so we voted for Grigorievich. And things turned out pretty well. It proved to be the right decision. He began to turn the company around. Things did not change overnight, of course. There was a lot going on here. I remember some crooks coming from Russia or elsewhere trying to buy the plant. They were rumoured to offer $20 million, or $40 million, $60 million. This is nothing for such an enterprise like ours. Grigorievich did not allow selling the company, and the plant began to recover little by little,” Aleksandr Loskov recalled.

The Belarusian authorities went their own way. They did not shut down factories. Neither did they allow privatizing them, which was a popular trend back then. They decided to help factories get back on their feet. They were built by the state, in other words, using people’s money, so would it be fair to sell them for a song? The refusal to sell the country’s best assets defied the prevailing trend of those times, so the government got a lot of flak for it. At first, Belarusian enterprises were predicted to go on just for several more weeks, then for several months, then until the next presidential election. But against all odds, factories and enterprises managed to turn the corner. It’s true, they were still far from their heyday, but at least they remained afloat. And they worked for people, not for a bunch of deep-pocketed businessmen, Aleksandr Lukashenko emphasized.

Why was Aleksandr Lukashenko commended by the plant?

During the crisis, the head of state decided to allocate $25 million to bail out BMZ. Production facilities were renovated, and the near-bankrupt company returned to consistently stable performance with an output of $850 million.

“They were pushing us to sell the company into private ownership. They insisted that unless we do it, the company will be doomed. The situation was dire, indeed. When we decided to open new workshops, we also faced many challenges. When our competitors realized that we were able to bail out and run this company on our own, they went out of their way trying to put pressure on us. And now there is not a single corner of the plant that stays idle,” the president said during his visit to BMZ in October 2004.

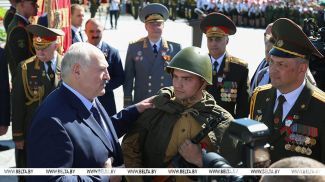

To show appreciation for his significant contribution to the company’s turnaround, the workers awarded Aleksandr Lukashenko with the silver badge “Honorary Worker of Belarusian Steel Works.”

Several years later the president visited the plant again: in 2007 he took part in the launch of the pipe-rolling complex. While talking to the workers, he said: “At a time when all assets in the post-Soviet space were auctioned off, when privatization was massive and indiscriminate and even outright illegal, it was difficult for me, a fledgling politician, to decide what way to go. But when I looked at you, I saw a strong resolve in your eyes, and it gave me confidence to try to get the company out of the woods. And other factories, plans, enterprises, too. So we went our own way. The bottom line is: I do not regret my efforts, the efforts of the entire state, the entire nation. Because you are giving back what you have been receiving from the state for the past 10 years.”

“We have built on what we preserved thanks to the company’s management and the country’s leadership. You need to work hard and smart. If you work as if you are doing it for yourself, for your home, for your family, you will be of great use to the country and the plant. Our republic is a case in point. It’s very nice to see that everything is in order here. We try not to be an outlier. What is most important for a worker is to have confidence in the future. Of course, the plant can give such confidence. Whatever challenges we encounter, we respond with our solutions, our work. I think we can handle any difficulties," said Aleksandr Tormanov, deputy head of the Metallurgical Equipment Repair Shop.

Why did BMZ have to be upgraded in the 2010s?

BMZ continued to grow. It opened new workshops and created new jobs. The city greatly benefited from the company’s expansion. It’s true, the company had its ups and downs. The history of Belarusian industry flagships is a bumpy road, rather than a straight path. They are export-oriented, so any market fluctuations or political upheavals have a toll on their performance. The ability to maneuver and to turn crisis into opportunities has long been a distinctive feature of Belarusians.

“There are few countries in the world that are self-sufficient in metallurgy products, foodstuffs and other goods. As they say, no pain no gain. If you work to the best of your ability, you will be acknowledged and appreciated. There is no order without discipline. Kindness is often mistaken for weakness," said Yevgeny Gavrilenko, electric and gas welder at the Metallurgical Equipment Repair Shop.

In the 2010s, Belarusian Steel Works underwent a full-scale renovation and upgrade. New investment projects covered all technological processes of the enterprise: from provision of auxiliary raw materials to production of innovative high-tech metal products with higher added value. Today, the enterprise runs the entire technological cycle - from production of high-strength steel to manufacturing of finished products like rolled metal, pipes, wire, steel fiber. In September 2015 the president took part in the launch of a new wire-rod mill at the company.

"We have built the plant. We have built an additional workshop. This had to be done, because selling a semi-finished product is nearly criminal. We need to make finished products. Why? Because it brings more profit, more revenues for the company, hence bigger salaries and more tax revenues for the budget. But I want to make one thing clear: you are not the only ones asking for help in this difficult time, we must join efforts to pull through. You will have to cut production costs. I am glad that another 500 people, especially young people, will get jobs here. As I have been told, the average age of people working in this workshop is 32 years. So this is a youth workshop. This is the future for our country,” Aleksandr Lukashenko said back then.

Just imagine: the area of Belarusian Steel Works is 257 hectares - more than the territory of the Principality of Monaco.

BMZ products are well-known in more than 100 countries. These products are used in construction projects all over the world and even in... Antarctica. Here is a recent example. In late January Russia launched a new wintering complex at the Antarctic research station Vostok. BMZ pipes were used in the construction of the complex.

“Huge investments of more than $1 billion have been injected into the enterprise over the past 12-14 years. Two new production facilities have been put into operation. Innovative products accounted for 41% of the output last year. This means that all the recent sanctions encouraged us to move forward, develop new products, new technologies. Today the enterprise is doing great. In 2023 steel production increased by 250,000 tonnes, or up by 12%. The export of ferrous metal rolled products went up 17%, which means we sold 1.6 million tonnes of ferrous metal rolled products abroad. In 2023, we supplied a pilot batch of our products to China, despite high competition and the fact that China is among the world leaders in metallurgy. We ensured returns on sales, which made it possible to increase wages and pay our workers the 13th salary bonus at the end of 2023,”Dmitry Korchik, Director General of Belarusian Steel Works, said.

Just for the record. Maternity leave for BMZ employees is granted from the second month of pregnancy, not from the seventh one. A few years ago, the enterprise’s collective agreement was amended to include a norm enabling expectant mothers to take time off work in early stages of pregnancy with the preservation of full pay until the maternity leave is granted. COVID was the original reason behind this decision. When the pandemic began, the management started to think how to protect the workers. An executive order was issued to let pregnant women stay out of work with their average earnings kept intact. After multiple extensions, this norm was formalized as a social guarantee.

According to veteran worker Lyubov Gubina, the enterprise has become not just a place of work for her, but also a reliable friend, while its team - a close family.

“The worker feels protected at any state-run enterprise. Workers at such companies cannot be fired without a reason. It is not always the case at private companies. Here is an example from my life. I am a pensioner, which means my salary is not very big. They fired a young woman with two children and decided to keep me as they had to pay me less. The owner simply said: “I don't need her.” Such things never happened at a state enterprise. The plant is my family. I have had a lot of problems in my life. My son got injured in a car accident. It was a terrible accident. He got a head injury. It took us four years to teach him to speak again. And he still has difficulty speaking. The plant supported us. The workers brought flax seeds (at that time there were no mattresses preventing bedsores), and he lay on them. They did everything possible to help. According to the collective agreement, the worker leaves as soon as he/she reaches the retirement age. They let me stay because I had two grandchildren. Even in this case the enterprise supported me,” Lyubov Gubina recalled.

Who and why called the star in honor of Belarusian Steel Works?

What about the Orion constellation? In 2015, the Lithuanian partner of BMZ decided to make a gift to the Belarusian enterprise as a sign of respect for the successes and labor achievements of its team. One of the stars in the Orion constellation was named in honor of Belarusian Steel Works.

The corresponding entry has been made in the International Catalog of Heavenly Bodies. By the way, the constellation contains more than 200 stars visible to the naked eye. The distance from BMZ to the star of the same name is equal to 650 light-years. That means, the light needs 650 years to travel from this star to Earth. By comparison, it is only eight light-minutes from Earth to the Sun. In the context of the universe, it is just a stone's throw away.

Why was Lukashenko offered to move the capital city to Zhlobin?

However, that was not the reason behind the proposal to move the Belarusian capital to Zhlobin. Belarusian Steel Works is the general sponsor of HC Metallurg Zhlobin. The hockey team has repeatedly graced the podium, and secured the Belarusian Extraleague champion title in 2022.The Steel Wolves faced Yunost Minsk in that final, and the match was held at Minsk Arena. Aleksandr Lukashenko attended the match. During the award ceremony the head of state presented the trophy, Belarus President Cup, to HC Metallurg Zhlobin. The atmosphere in the arena was incredible!

“I’ve just heard an interesting proposal here. I guess it was meant for my ears. Our great players who came to Minsk for the match made a proposal to move the capital to Zhlobin. Look, it is very expensive, but I'll think about it,” the head of state said stepping out on the ice rink.

“If we love and support our athletes as much as the fans from Zhlobin did today, no sanctions will be an obstacle for us. I would also like to say a few words about Belarusian Steel Works. It is thanks to it, to its labor collective that you have the chance to play on this ice. Remember, appreciate, and respect these people. The first thing you should do when you return home is to pay a visit to BMZ so that its workers can greet you, the winners. It is very important for them today,” Aleksandr Lukashenko stressed.

The president is right: the plant workers, their hard work and perseverance, have made a strong hockey team. I’ll tell you more. Ordinary workers, whom are tens of thousands in Belarus, have made a strong country. Let's not forget about it.